Nyob rau hauv lub ntiaj teb no ntawm niaj hnub manufacturing, kev cai txhaj tshuaj molding tau dhau los ua lub hauv paus ntawm scalable, high-precision ntau lawm. Txawm hais tias yog rau cov khoom siv kho mob, cov khoom siv hluav taws xob, cov khoom lag luam, lossis cov khoom siv tsheb, cov txheej txheem tsim khoom no muaj kev sib koom ua ke ntawm kev sib luag, kev siv nyiaj txiag, thiab kev siv ntau yam-tshwj xeeb tshaj yog thaum ua raws li cov kev xav tau tshwj xeeb ntawm cov khoom.

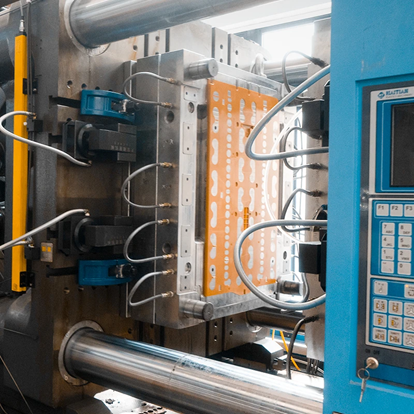

Kev txhaj tshuaj molding ua haujlwm los ntawm kev txhaj tshuaj molten-feem ntau yog yas-rau hauv cov pwm tsim los ntawm kab noj hniav. Thaum txias, cov ntaub ntawv solidifies rau hauv qhov kawg, replicating txawm lub feem ntau intricate cov ntsiab lus ntawm pwm nrog exceptional raug. Rau cov tuam txhab nrhiav cov khoom ntim siab nrog nruj kam rau ua thiab rov ua tau zoo, kev txhaj tshuaj molding feem ntau yog cov kev daws teeb meem.

Qhov twg kev cai txhaj tshuaj molding teem nws tus kheej sib nrug yog nyob rau hauv lub peev xwm los tsim pwm thiab qhov chaw uas yog tag nrho tailored rau cov khoom tsim, kev ua tau zoo, thiab lub zeem muag zoo nkauj. Tsis txhob cia siab rau cov kev daws teeb meem sab nraud, cov lag luam tuaj yeem ua tiav kev tswj hwm ntawm cov khoom siv, cov khoom tiav, ib feem geometry, xim, thiab cov yam ntxwv ua haujlwm.

Ntawm Minewing, peb muab cov kev pabcuam txhaj tshuaj molding kawg-rau-kawg-los ntawm kev tsim rau kev tsim khoom (DFM) thiab kev tsim pwm rau cov qauv pov thawj thiab kev tsim khoom kawg. Peb pab neeg ua haujlwm engineering ua haujlwm zoo nrog cov neeg siv khoom ntawm txhua theem los txhim kho qhov tsim qauv, xaiv cov resins uas tsim nyog tshaj plaws lossis cov khoom sib xyaw, thiab xyuas kom meej tias txhua qhov kev nthuav dav ua raws li kev ua tau zoo thiab kev ua haujlwm ntev.

Ib qho ntawm qhov zoo tshaj plaws ntawm kev cai txhaj tshuaj molding yog nyob rau hauv nws adaptability. Txawm hais tias tus neeg siv khoom xav tau ib qho qauv pwm rau kev sim lossis ntau kab noj hniav steel pwm rau ntau lawm, cov txheej txheem tuaj yeem ntsuas raws li. Tsis tas li ntawd, cov txheej txheem thib ob xws li overmolding, ntxig molding, thiab cov ntaub ntawv saum npoo tuaj yeem ua ke los txhim kho cov khoom lag luam thiab kev rov hais dua.

Hauv kev lag luam thoob ntiaj teb uas muaj nuj nqis rau kev ceev, kev ntseeg siab, thiab kev tsim kho tshiab, koom tes nrog tus kws kho mob muaj peev xwm thiab paub txog kev txhaj tshuaj molding yog qhov tseem ceeb rau kev ua tiav. Minewing coj ntau tshaj li ob xyoo caum ntawm kev paub hauv kev tsim khoom, txhawb cov neeg siv khoom los ntawm kev tsim khoom los ntawm kev tsim khoom nrog kev txhawb nqa cov saw hlau, kev tswj kom zoo, thiab kev ua raws li kev lees paub thoob ntiaj teb.

Los ntawm lub tswv yim mus rau qhov tseeb, peb Cov Kev Cai Txhaj Tshuaj Moulding Service pab coj koj lub zeem muag mus rau lub neej - raug, ua tau zoo, thiab ntawm qhov ntsuas.

Lub sij hawm xa tuaj: Plaub Hlis-13-2025