Ob chav txhaj tshuaj molding (tseem hu ua ob-shot molding) tau txais traction thoob plaws kev lag luam rau nws lub peev xwm los tsim complex, ntau yam khoom siv hauv ib lub voj voog tsim khoom. Cov txheej txheem qib siab no tso cai rau cov tuam txhab tsim cov khoom sib txawv ntawm cov polymers-xws li cov yas khov thiab hloov tau yooj yim-rau hauv ib qho kev sib koom ua ke, tshem tawm qhov xav tau ntawm kev sib koom ua ke.

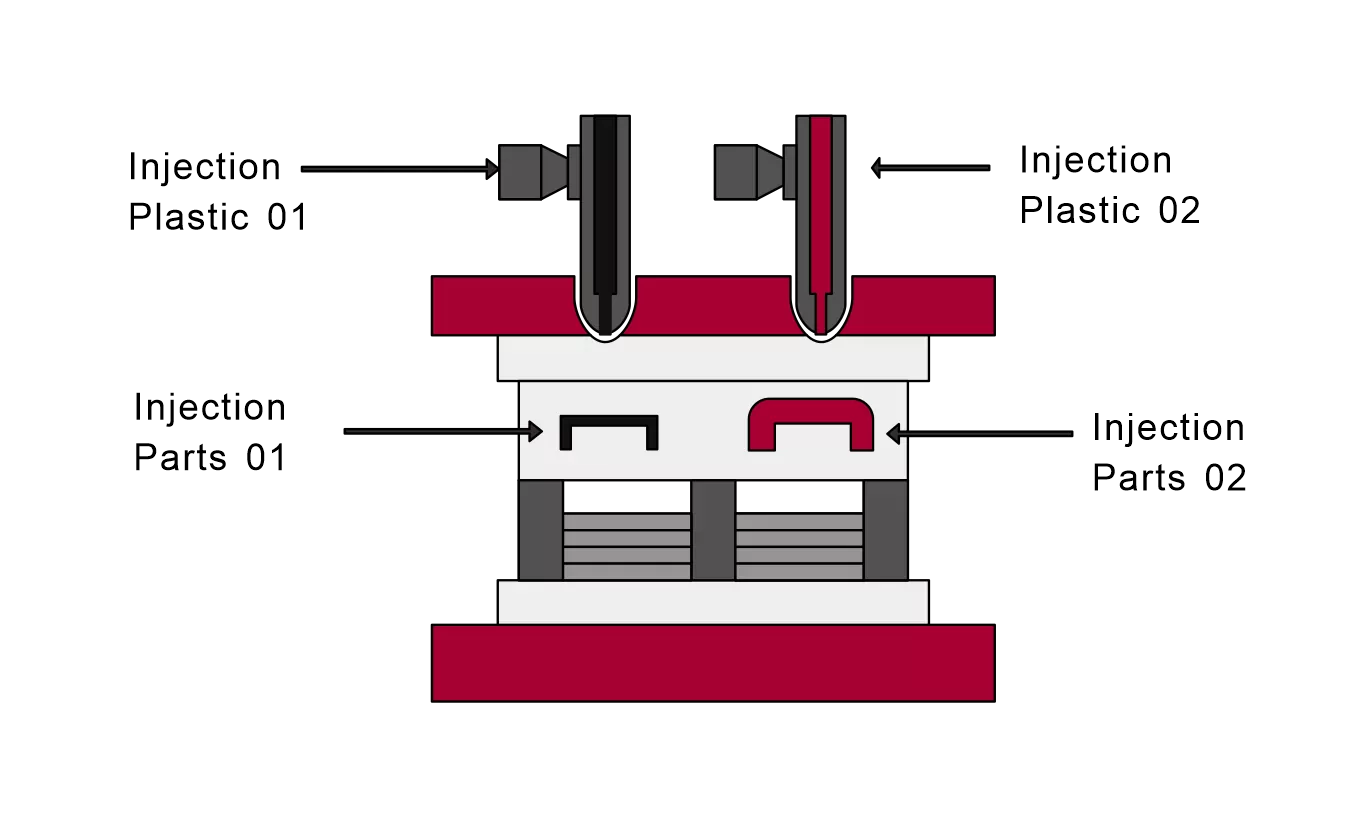

Cov txheej txheem suav nrog kev txhaj tshuaj a thawj cov ntaub ntawv rau hauv pwm, ua raws li a khoom siv thib ob uas bonds seamlessly nrog thawj txheej. Txoj kev no yog siv dav hauv automotive, cov khoom siv kho mob, cov khoom siv hluav taws xob, thiab cov khoom siv, qhov twg durability, ergonomics, thiab kev zoo nkauj yog qhov tseem ceeb.

Cov txiaj ntsig tseem ceeb ntawm kev txhaj tshuaj molding muaj xws li:

-Txhim kho cov khoom ua haujlwm zoo (xws li, mos-kov tuav ntawm cov cuab yeej yas tawv)

-Txo cov nqi tsim khoom los ntawm kev txo qis cov kauj ruam sib dhos

-Kev txhim kho cov qauv kev ncaj ncees piv rau cov khoom sib txuas los yog welded

-Kev tsim qauv yooj yim dua rau cov geometry intricate

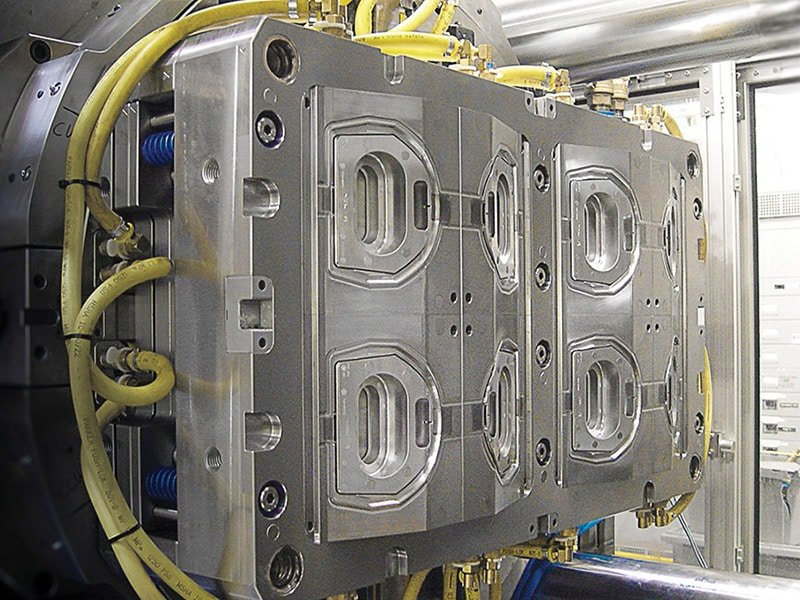

Kev nce qib tsis ntev los no hauv kev tsim pwm thiab cov khoom siv sib xws tau nthuav dav rau kev txhaj tshuaj molding ob npaug. Cov neeg tsim khoom tam sim no tau sim nrog cov thermoplastic elastomers (TPEs), silicone, thiab cov khoom siv hluav taws xob los tsim cov khoom sib xyaw tshiab.

Raws li kev lag luam xav tau ntau dua, cov khoom lag luam ua tau zoo, ob chav txhaj tshuaj molding tau teeb tsa los ua lub luag haujlwm tseem ceeb hauv kev tsim khoom tshiab.

Post lub sij hawm: Jul-03-2025