Nyob rau hauv niaj hnub no evolving sai heev electronics kev lag luam,enclosure tsimtau tshwm sim los ua ib qho tseem ceeb hauv kev txiav txim siab qhov kev vam meej ntawm cov khoom. Ib lub hnab ntim khoom yog ntau tshaj li lub plhaub tiv thaiv; nws embodies cov khoom tus kheej, usability, thiab durability.

Cov neeg siv khoom niaj hnub xav tias cov khoom siv hluav taws xob tsis yog tsuas yog ua tau zoo xwb tab sis kuj yuav saib zoo nkauj, xis nyob, thiab tiv taus ntau yam teeb meem ib puag ncig. Cov neeg tsim khoom hauv tsev yuav tsum sib npaug ntawm kev zoo nkauj, ergonomics, kev tswj xyuas thermal, thiab kev tsim khoom, feem ntau ua rau kev lag luam nyuaj.

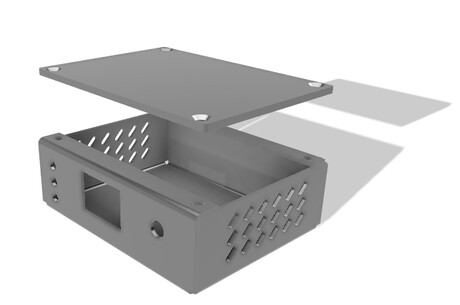

Ib qho ntawm cov ntsiab lus tseem ceeb hauv kev tsim cov kab ke yogthermal tswj. Nrog cov cuab yeej ua kom sib zog ua kom muaj zog dua, kev siv hluav taws xob zoo yog qhov tseem ceeb los xyuas kom muaj kev ntseeg siab thiab tiv thaiv kev ua tsis tiav ntxov. Cov neeg tsim qauv tsim cov vents, cov dab dej kub, thiab txawm tias cov txheej txheem txias txias xws li cov kua txias lossis cov kav dej kub los daws qhov kev sib tw no.

Lwm qhov tseem ceeb yogxaiv cov khoom siv. Nyob ntawm daim ntawv thov, cov neeg tsim qauv xaiv los ntawm cov yas, hlau, cov khoom sib xyaw, lossis cov khoom sib xyaw. Piv txwv li, hlau enclosures muab superior durability thiab electromagnetic cuam tshuam (EMI) shielding tab sis tej zaum yuav nce nqi thiab hnyav. Cov yas tso cai rau cov duab thiab xim ntau dua thiab txo qhov hnyav, tab sis yuav xav tau kev kho mob ntxiv los txhim kho toughness thiab kub tsis kam.

Tsis tas li ntawd,ergonomicsplays lub luag haujlwm tseem ceeb, tshwj xeeb tshaj yog rau cov khoom siv tes tuav lossis nqa tau yooj yim. Lub kaw lus yuav tsum xav tias intuitive thiab xis rau cov neeg siv thaum siv txuas ntxiv. Nta xws li textured grips, strategically muab nyees khawm, thiab pom qhov ceeb thawj faib yog feem ntau meticulously engineered.

Cov txheej txheem tsim khoom nws tus kheej kuj cuam tshuam rau kev tsim vaj tsev. Cov neeg tsim qauv yuav tsum xyuas kom meej tias lub kaw lus tuaj yeem ua tau zoo ntawm qhov ntsuas, xav txog kev tsim pwm rau kev txhaj tshuaj molded yas lossis cov txheej txheem machining rau hlau. Kev kam rau siab thiab kev sib dhos tuaj yeem cuam tshuam cov nqi tsim khoom thiab cov khoom zoo.

Hauv cov ntsiab lus, kev tsim vaj tsev yog ib qho kev sib koom ua ke uas sib koom ua ke kos duab, engineering, thiab kev tsim khoom. Cov ntaub ntawv muaj txiaj ntsig zoo tiv thaiv cov khoom siv hluav taws xob zoo, txhim kho cov neeg siv kev paub, thiab sib txawv cov khoom lag luam hauv kev sib tw. Raws li kev siv thev naus laus zis thiab kev cia siab ntawm cov neeg siv tau nce, kev tsim cov ntaub thaiv npog yuav txuas ntxiv mus ua qhov tseem ceeb sib ntaus sib tua rau kev tsim kho tshiab.

Post lub sij hawm: Lub Xya hli ntuj-24-2025