I-PCBA inqubo yokukhweza izingxenye ze-elekthronikhi ku-PCB.

Sikuphathela zonke izigaba endaweni eyodwa.

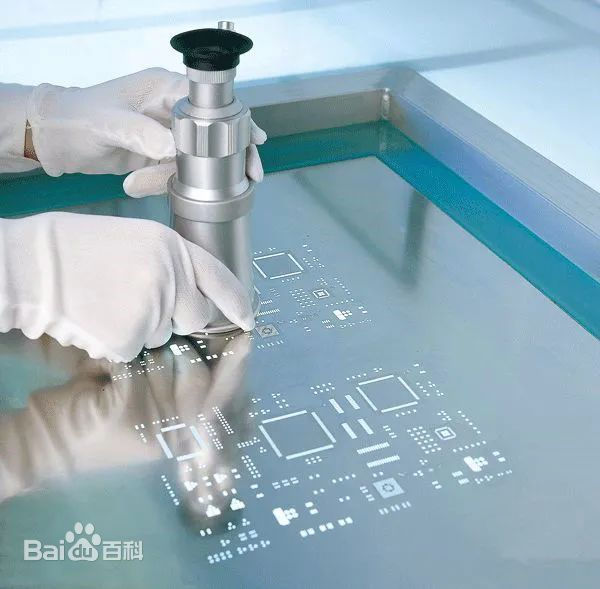

1. I-Solder Namathisela Ukuphrinta

Isinyathelo sokuqala ekuhlanganiseni kwe-PCB ukuphrinta kokunamathisela kwe-solder ezindaweni zephedi zebhodi le-PCB. I-solder paste iqukethe i-tin powder kanye ne-flux futhi isetshenziselwa ukuxhuma izingxenye kumaphedi ngezinyathelo ezilandelayo.

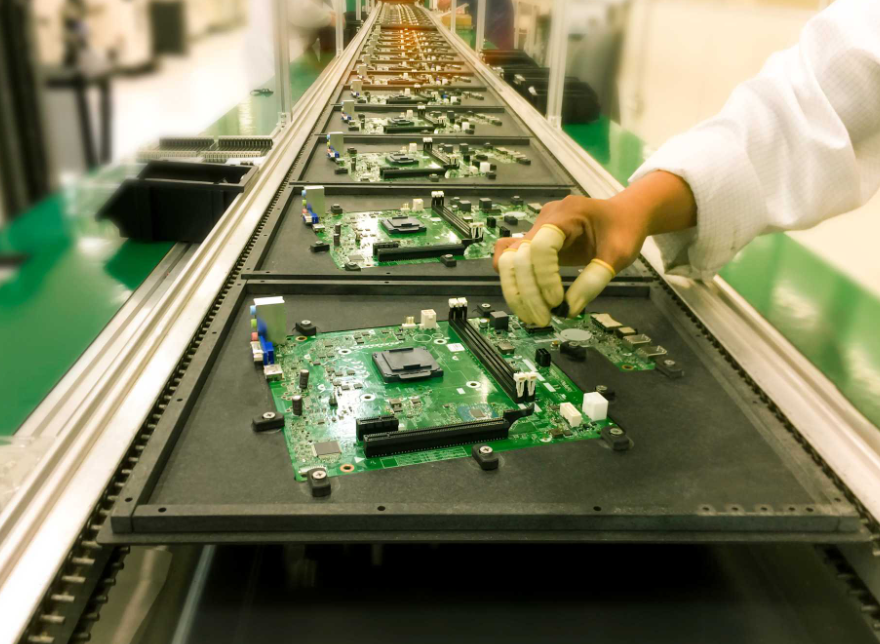

2. I-Surface Mounted Technology(SMT)

I-Surface Mounted Technology(izingxenye ze-SMT) zibekwe phezu kwe-solder paste kusetshenziswa i-bonder. I-bonder ingabeka ngokushesha futhi ngokunembile ingxenye endaweni ethile.

3. I-Reflow Soldering

I-PCB enezingxenye ezinamathiselwe idluliswa kuhhavini wokugeleza kabusha, lapho i-solder paste incibilika ekushiseni okuphezulu futhi izingxenye zithengiswa ngokuqinile ku-PCB. I-Reflow soldering iyisinyathelo esibalulekile ekuhlanganiseni kwe-SMT.

4. Ukuhlola Okubonakalayo kanye Nokuhlola Okuzenzakalelayo Kwamehlo (AOI)

Ngemva kokudayiswa kabusha, ama-PCB ahlolwa ngokubonakalayo noma ahlolwe ngokuzenzakalelayo kusetshenziswa okokusebenza kwe-AOI ukuze kuqinisekiswe ukuthi zonke izingxenye zithengiswa ngendlela efanele futhi azinasici.

5. I-Thru-Hole Technology (THT)

Ezingxenyeni ezidinga ubuchwepheshe be- through-hole (THT), ingxenye ishutheka emgodini we-PCB ngokwenza noma ngokuzenzakalelayo.

6. I-Wave Soldering

I-PCB yengxenye efakiwe idluliswa emshinini wokugcwalisa i-wave soldering, futhi umshini we-wave soldering ushisela ingxenye efakiwe ku-PCB ngokusebenzisa igagasi le-solder encibilikisiwe.

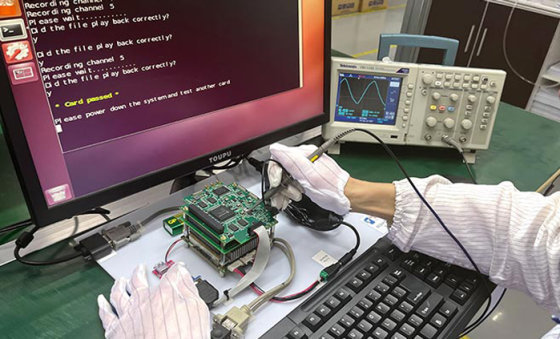

7. Ukuhlolwa Komsebenzi

Ukuhlola okusebenzayo kwenziwa ku-PCB ehlanganisiwe ukuze kuqinisekiswe ukuthi isebenza kahle ohlelweni lwangempela. Ukuhlola okusebenzayo kungabandakanya ukuhlolwa kukagesi, ukuhlolwa kwesignali, njll.

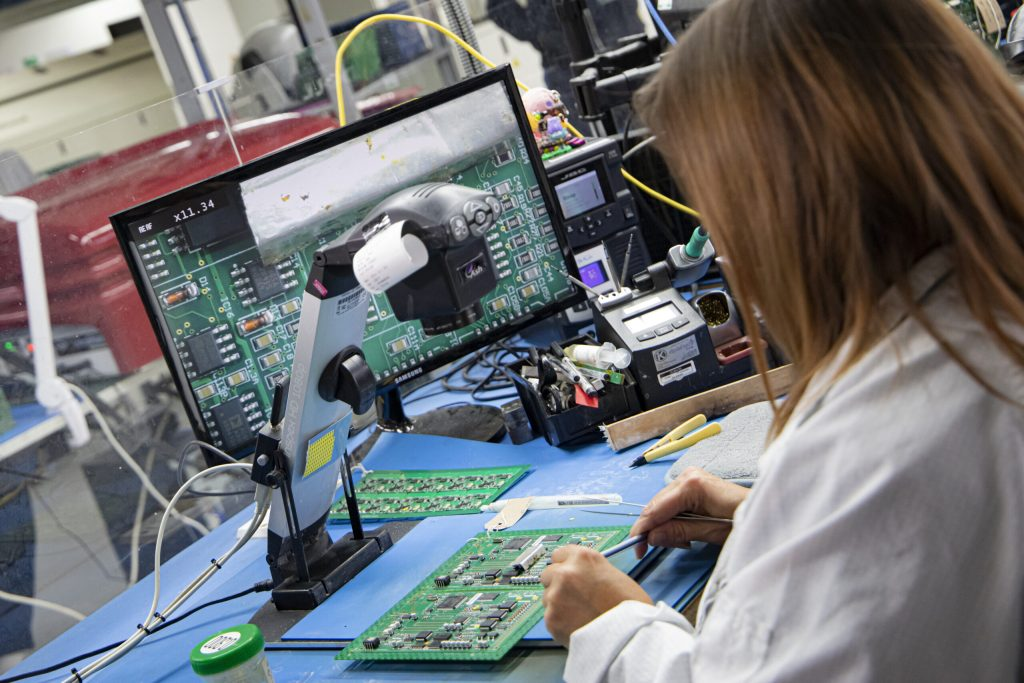

8. Ukuhlolwa Kokugcina Nokulawulwa Kwekhwalithi

Ngemuva kokuthi zonke izivivinyo nezincane seziqediwe, ukuhlolwa kokugcina kwe-PCB kwenziwa ukuze kuqinisekiswe ukuthi zonke izingxenye zifakwe ngendlela efanele, azinasici, futhi ngokuhambisana nezidingo zokuklama kanye namazinga ekhwalithi.

9. Ukupakisha kanye Nokuthumela

Okokugcina, i-PCB ephumelele isheke lekhwalithi iyapakishwa ukuze kuqinisekiswe ukuthi ayonakaliswa ngesikhathi sokuthutha bese ithunyelwa kumakhasimende.

Isikhathi sokuthumela: Jul-29-2024