Box Build System Integration: Turning Components into Complete Products

In a world where innovation and speed define success, manufacturers are increasingly looking for turnkey solutions that go beyond simple PCB assembly. Box Build System Integration—also known as system-level integration—has become a critical manufacturing capability that transforms multiple components into a fully functional end product.

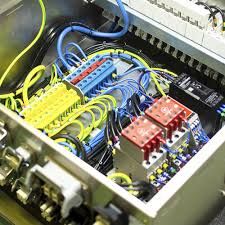

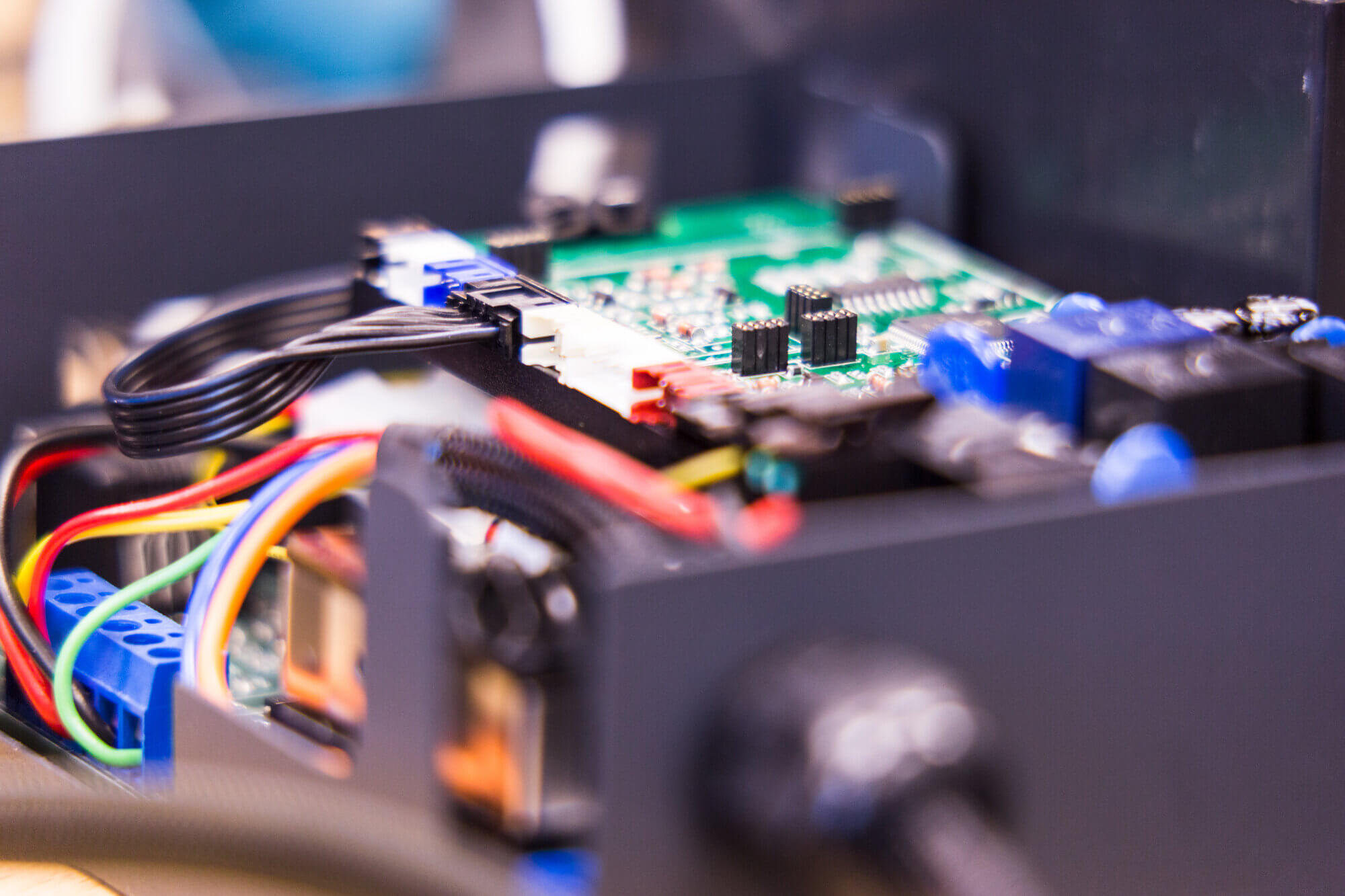

Box build includes the complete assembly of mechanical and electronic components into enclosures, ready for deployment or direct-to-consumer shipping. This may involve mounting PCBs, wiring harnesses, displays, batteries, power systems, antennas, and connectors. It can also extend to firmware loading, software installation, calibration, and complete end-of-line testing.

What sets advanced box build services apart is the ability to handle complex integration efficiently while maintaining quality and scalability. At our facility, we provide flexible assembly lines for low to high-volume box builds, cleanroom environments where necessary, and real-time traceability through MES systems.

Clients rely on us for fast-turn prototype assemblies as well as full-scale production runs. With expertise across industries such as smart home, medtech, industrial IoT, and consumer electronics, we adapt to diverse product needs and regulatory requirements. Our ability to manage sourcing, logistics, and quality assurance across the supply chain gives our partners peace of mind and a faster path to market.

By offering one-stop system integration, we help innovators move from concept to shelf-ready product with fewer risks, lower costs, and reduced time-to-market. Whether you are scaling up a pilot run or launching globally, our box build solutions ensure that your product is more than the sum of its parts—it’s market-ready, reliable, and built to perform.

Post time: Jun-15-2025