Complex Enclosure Build: Engineering Form and Function into Every Device

Designing and producing enclosures for modern electronic devices is no longer just about protection—it’s about integration, precision, and user experience. Complex Enclosure Build is a specialized area of product development where mechanical engineering, material science, and aesthetic design converge to deliver enclosures that are as intelligent as the electronics they protect.

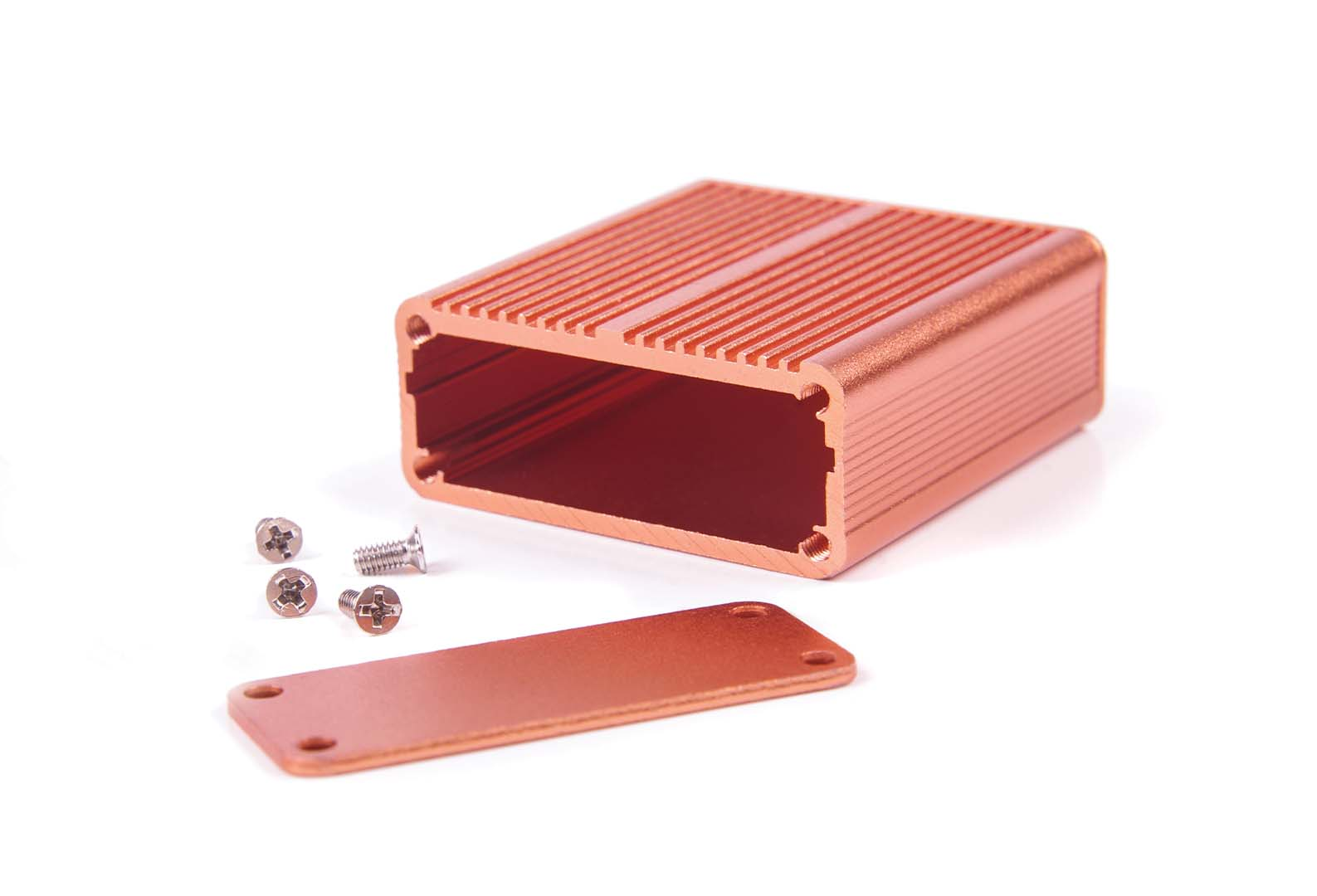

Complex enclosures often serve multiple purposes: they house and protect sensitive internal components, provide heat dissipation or waterproofing, enable signal transparency for wireless communication, and support usability through touchpoints or buttons. Designing such enclosures requires a deep understanding of structure, assembly methods, materials, and environmental factors.

At our facility, we specialize in designing and manufacturing multi-part, high-precision enclosure systems. These may include snap-fit assemblies, threaded inserts, multi-material overmolding, EMI shielding, or rubber sealing for IP-rated protection. Whether your product is a handheld device, wearable, or industrial controller, we tailor the enclosure to its operational context.

Our engineering team uses advanced 3D modeling software and structural simulation tools to validate designs before production. We also offer 3D printing and CNC machining for rapid prototyping, followed by injection molding or die-casting for mass production.

We understand that a device’s success often depends on the quality of its enclosure—how it feels, looks, and performs in real-world use. That’s why our approach to complex enclosure builds goes beyond fabrication; we’re your development partner from early concept through testing and scaling.

With proven experience in healthcare, consumer tech, automotive, and wearables, we are ready to solve the most challenging enclosure requirements—bringing your design vision into reality, without compromise.

Post time: Jun-15-2025