Electronics manufacturers are accelerating digital and geographical transformation to meet market disruption and supply chain uncertainty. A trend report from Titoma outlines key strategies adopted in 2025, emphasizing AI-driven quality control, sustainability-focused design, and regional nearshoring initiatives. These efforts are reshaping the structure of global production and redefining competitiveness across the electronics industry.

In North America and Europe, manufacturers are bolstering regional production to mitigate risks associated with global logistics and trade tensions. For instance, North American EMS shipment volumes decreased 9.3% in May 2025, while PCB shipments surged 21.4%, signaling a strategic reallocation of production capacity. This shift suggests that while some traditional assembly volumes are being scaled back, investment is being redirected into high-value and resilient operations closer to end markets.

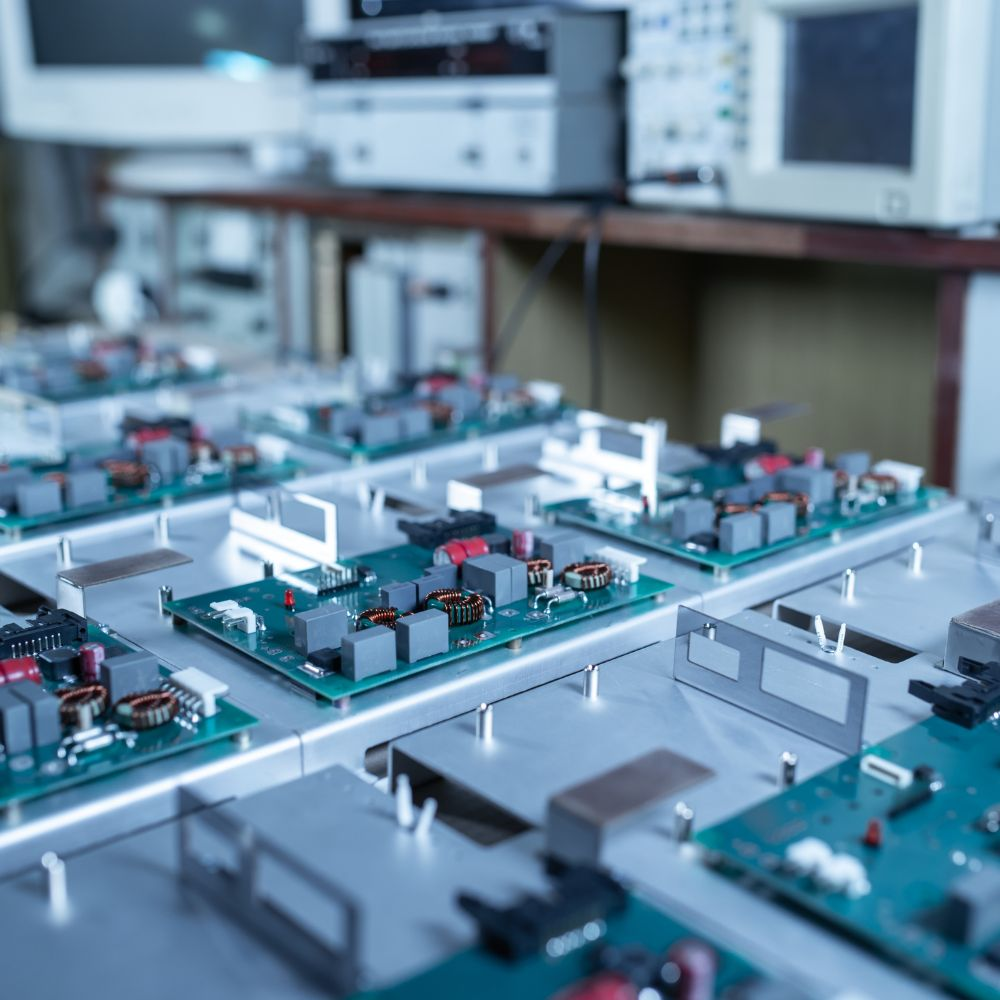

To reinforce manufacturing excellence, firms are deploying Industry 4.0 technologies, including AI-vision AOI systems, robotic SMT lines, and smart storage solutions. The adoption of digital inspection has become particularly widespread, as manufacturers prioritize zero-defect delivery and data-driven process control. Academic and industrial systems, such as DarwinAI’s DVQI, demonstrate strong return on investment by automating visual inspection processes on PCB assembly lines and delivering real-time analytics for predictive maintenance.

The manufacturing ecosystem is also becoming more interconnected. Crowd Supply, a platform known for helping hardware startups prototype and launch embedded systems, has introduced initiatives that offer developers up to $500 worth of free PCBA prototyping. These programs are fostering closer collaboration between early-stage innovators and full-scale manufacturers, bridging the gap between design and production. For experienced EMS providers, this represents a new opportunity to build long-term client relationships starting at the prototype stage.

As this transformation unfolds, electronics manufacturers are increasingly blending conventional EMS capabilities with smart, agile facilities located closer to key markets. From North American fabrication centers to European micro-factories, the trend signals a new era where digital precision, regional agility, and innovation partnerships converge to define manufacturing success.

Post time: Jul-07-2025