The electronic production sector is undergoing a significant transformation as robotics, vision inspection systems, and artificial intelligence become deeply embedded in factory operations. These advancements are enhancing speed, precision, and quality across the manufacturing lifecycle, positioning electronic production at the heart of the Industry 4.0 revolution.

Vision inspection systems are seeing substantial investment. According to Research And Markets, the market for these systems is expected to reach $9.29 billion by 2032, growing at a compound annual growth rate of 7.2%. Semiconductors and electronics remain the primary drivers of this growth, where machine vision, X-ray imaging, and thermal scanning ensure quality at micro and macro levels.

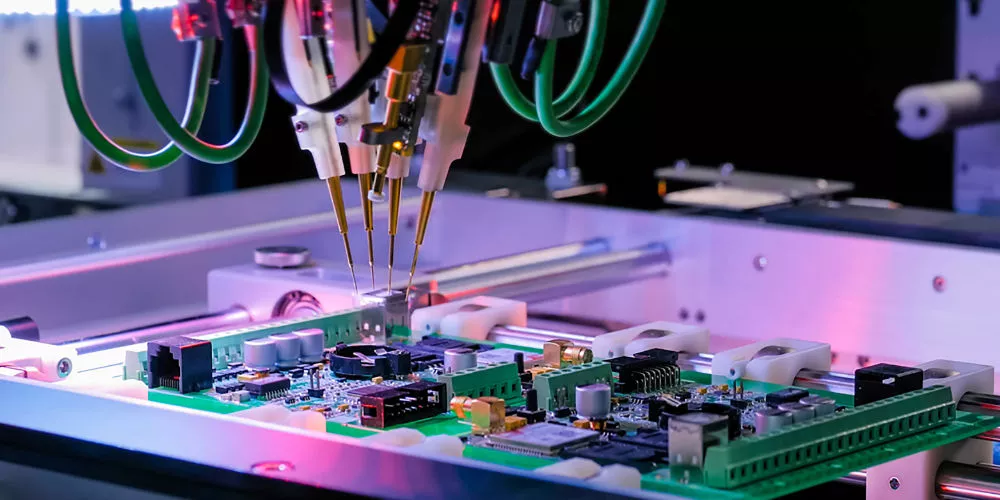

AOI systems, like the TRI TR7500 SIII Ultra, are redefining inspection capabilities with multiple high-resolution cameras and advanced algorithms. These machines are capable of detecting microscopic defects at production-line speeds, enabling real-time intervention and drastically reducing yield loss. Robotics is also becoming more integrated into electronics assembly, with companies like Vention offering plug-and-play robot cell platforms that help manufacturers adapt quickly to changes in design and demand.

AI-focused automation startups such as Bright Machines are also playing a transformative role. Backed by tech giants including Nvidia and Microsoft, they are developing integrated platforms that combine robotics, computer vision, and analytics to automate every step of the electronics assembly process. Their technologies are already being deployed in modular microfactories, promising faster and more localized production capabilities.

The academic community is contributing as well. Research like Darwin AI’s DVQI system showcases real-world applications of multi-task learning and visual inspection in PCB production, helping manufacturers reduce false positives and optimize throughput. These insights are increasingly being adopted in industrial lines where flexibility and accuracy are mission-critical.

Together, these advancements point to a future in which electronic production is shaped by smart, interconnected systems. Factories are becoming more agile, responsive, and sustainable through automation, not only improving output but also aligning with global efforts toward efficiency and carbon reduction.

Post time: Jul-07-2025