Mold Injection: Precision Engineering for Scalable, Durable Product Housing

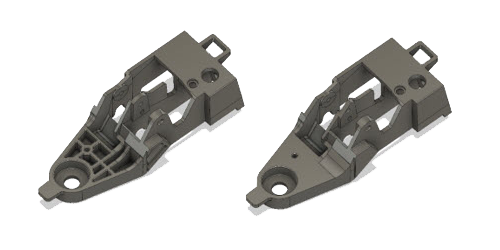

As industrial design becomes increasingly sophisticated, the demand for high-precision, aesthetically refined enclosures is at an all-time high. Mold injection has emerged as one of the most reliable and scalable solutions for creating custom plastic components that are both functional and beautiful.

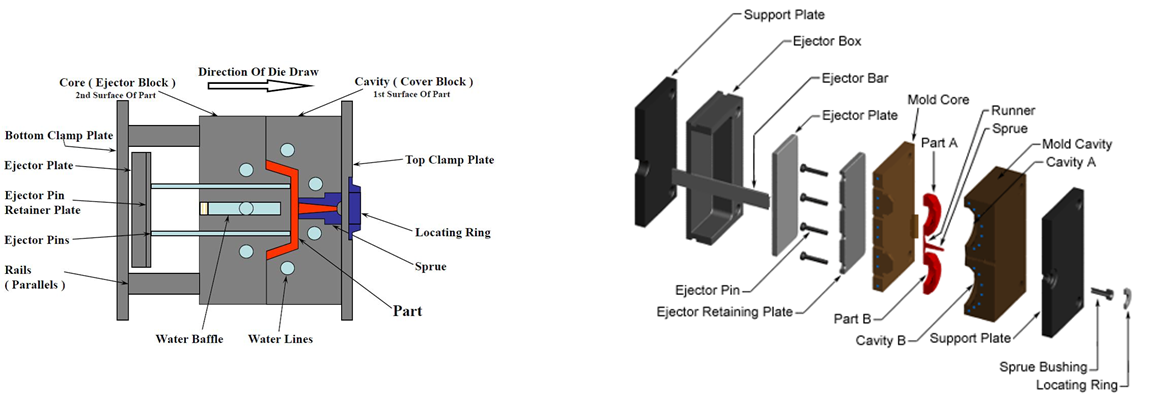

Mold injection is the process of injecting molten plastic into custom-designed molds to produce consistent parts with tight tolerances. It enables rapid mass production while ensuring strength, dimensional accuracy, and surface finish quality. This makes it ideal for a wide range of applications, from consumer electronics to automotive components and medical devices.

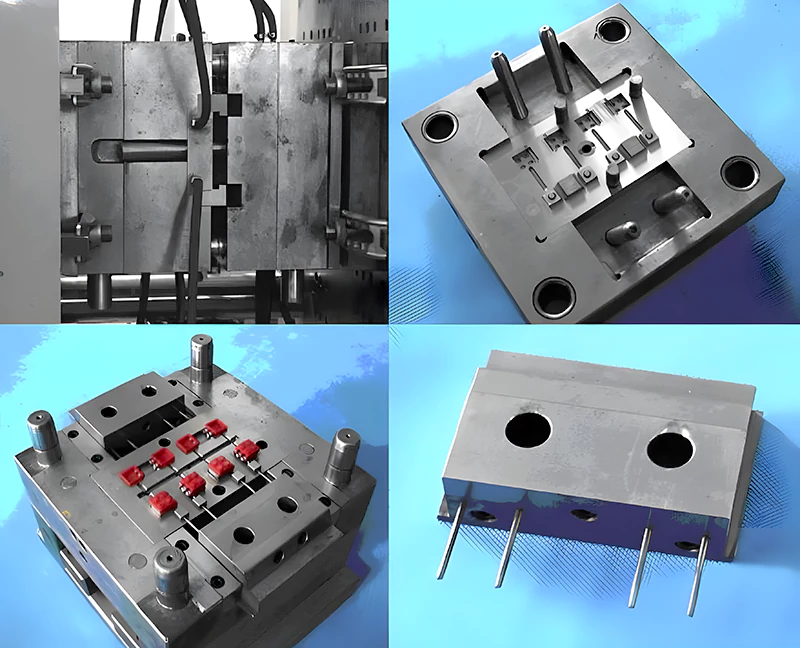

At our facility, we offer in-house mold design and manufacturing using high-grade steel and cutting-edge CNC machining. Our team works closely with clients from the DFM (Design for Manufacturability) stage to final production, ensuring that every design is optimized for injection molding.

We support a wide variety of thermoplastics—ABS, PC, PP, PA, and blends—with tailored material recommendations based on your product’s usage environment, durability requirements, and appearance goals. Whether your enclosure needs to be UV-resistant, flame-retardant, or high-gloss, we’ll help you choose the right material and surface treatment.

With mold maintenance programs and fast mold-change systems, we also reduce downtime and extend tool life for high-efficiency operations. Our mold injection capabilities are scalable for both low-volume prototyping and mass production runs.

In today’s competitive product environment, having a manufacturing partner that can deliver consistent, cost-effective, and high-quality molded parts is crucial. Our mold injection services empower brands to create products that look great, function perfectly, and stand the test of time.

Post time: Jun-15-2025