In today’s fast-paced tech environment, electronic manufacturing companies play a pivotal role in bringing innovative products to market. But what truly defines a leading electronic manufacturer today?

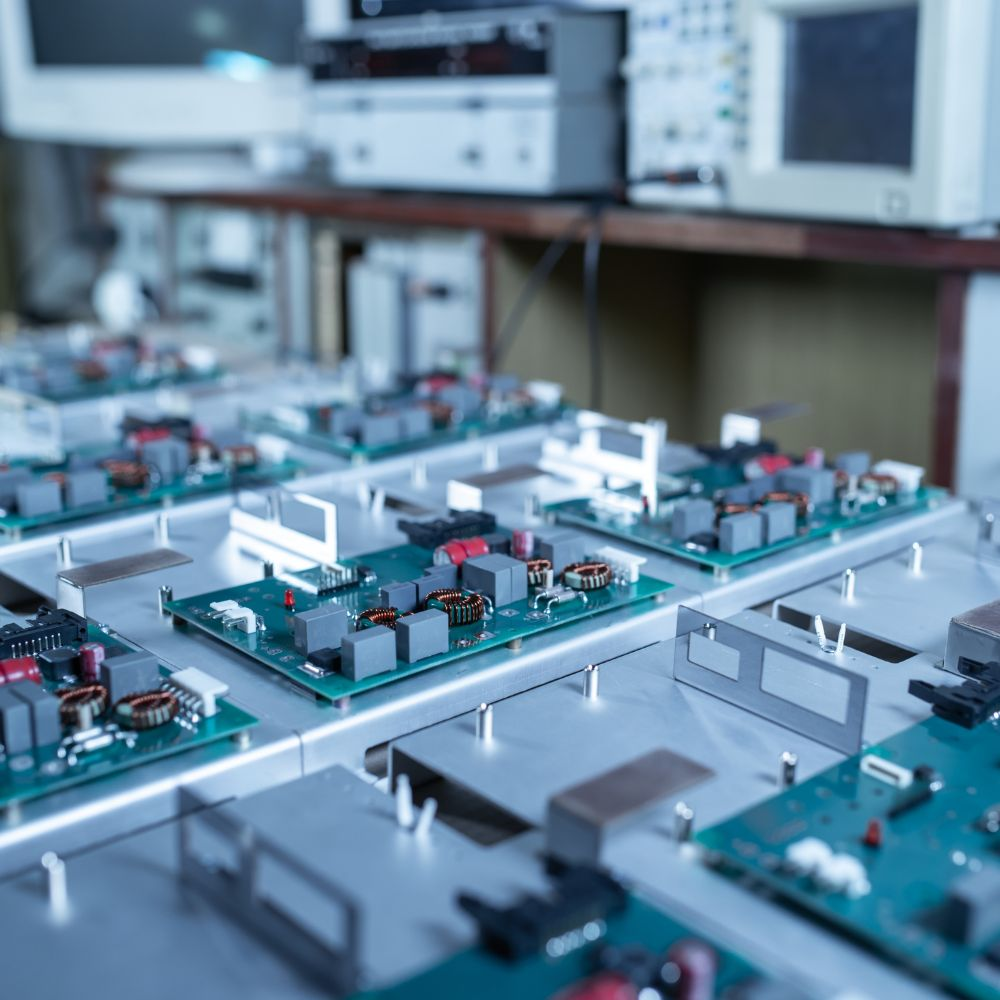

First and foremost, a top-tier electronic manufacturing company must demonstrate excellence across the entire production lifecycle. This includes prototyping, sourcing, SMT assembly, through-hole assembly, testing, quality assurance, and after-sales support. The ability to deliver turnkey solutions makes such companies invaluable to their clients.

Scalability is another critical factor. Leading manufacturers can handle both low-volume prototyping and high-volume mass production with equal precision. Their facilities are equipped with flexible assembly lines, modular machinery, and sophisticated software systems that allow quick adjustments based on customer requirements.

Certifications such as ISO 9001, ISO 13485 (medical), IATF 16949 (automotive), and IPC standards reflect their commitment to quality and compliance across various sectors. Clients from medical, aerospace, and defense industries particularly rely on certified partners who can meet stringent regulatory standards.

Another hallmark of a top electronic manufacturing company is their investment in technology and talent. Companies that adopt Industry 4.0 practices, including automation, real-time data analytics, and robotics, are setting new benchmarks in efficiency and traceability. Meanwhile, skilled engineers and technicians ensure that human oversight and innovation remain at the core of every project.

Finally, customer-centricity is key. Responsive communication, design feedback, and supply chain transparency make for strong, long-term partnerships. In an era of rapid innovation and shifting global dynamics, electronic manufacturing companies that combine technical excellence with strategic collaboration are best positioned for sustained growth.

Post time: Jul-14-2025