The global demand for advanced electronics has led to a transformation in the way companies approach production. At the heart of this transformation lies Electronic Manufacturing Services (EMS), a dynamic sector that supports a wide range of industries including telecommunications, automotive, medical, industrial, and consumer electronics.

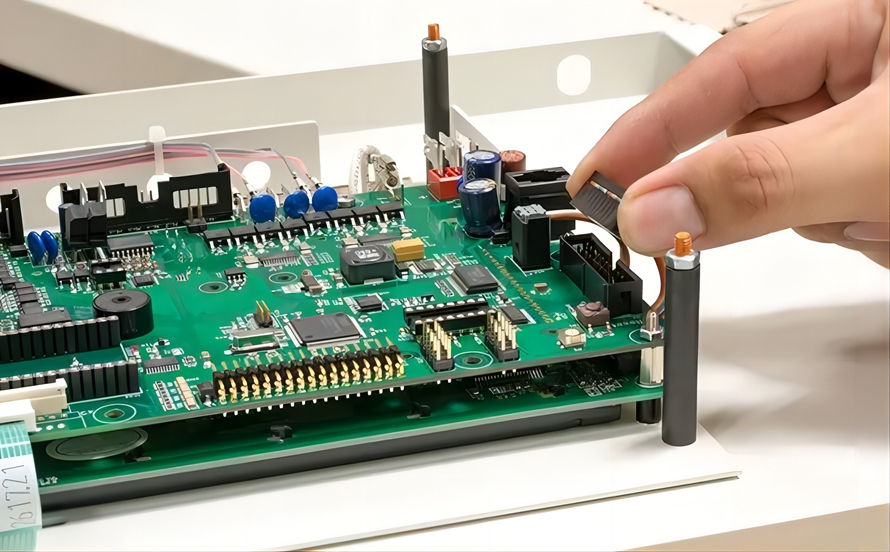

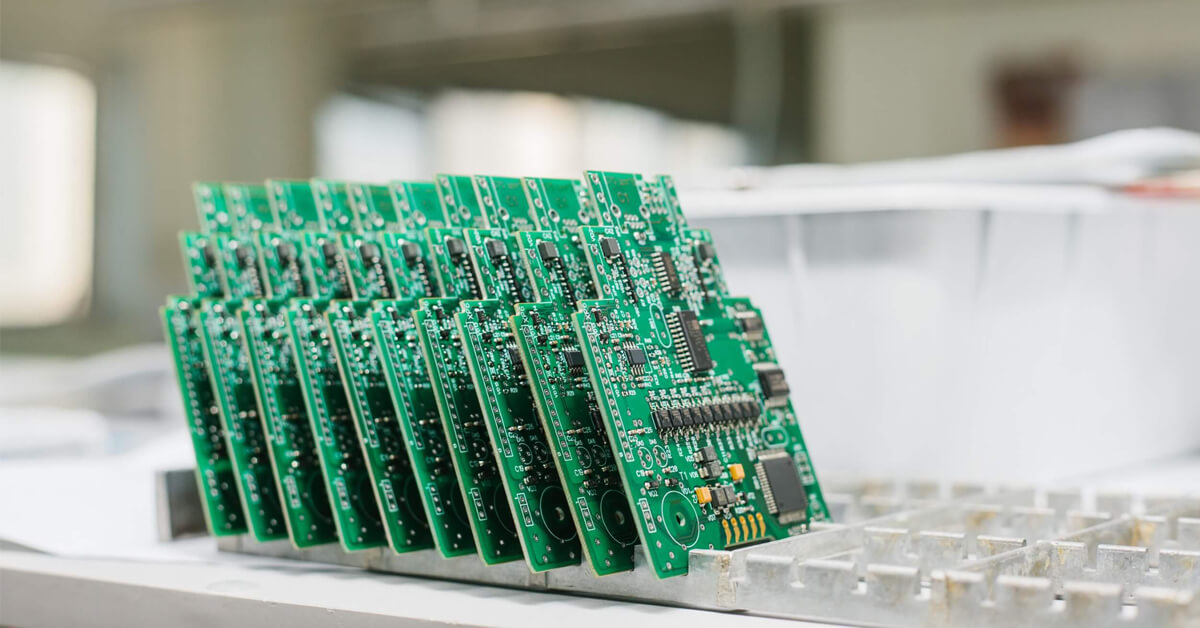

EMS providers offer a comprehensive suite of services: PCB fabrication, component procurement, assembly, testing, packaging, and even logistics. This one-stop-shop model significantly reduces complexity for OEMs and startups alike, enabling them to scale faster and respond more flexibly to market changes.

Recent trends show that companies are increasingly relying on EMS providers not just for volume production, but for engineering support, prototyping, and product lifecycle management. This shift is particularly important for startups and SMEs who may not have in-house manufacturing expertise or resources. EMS providers fill this gap with specialized teams and advanced facilities.

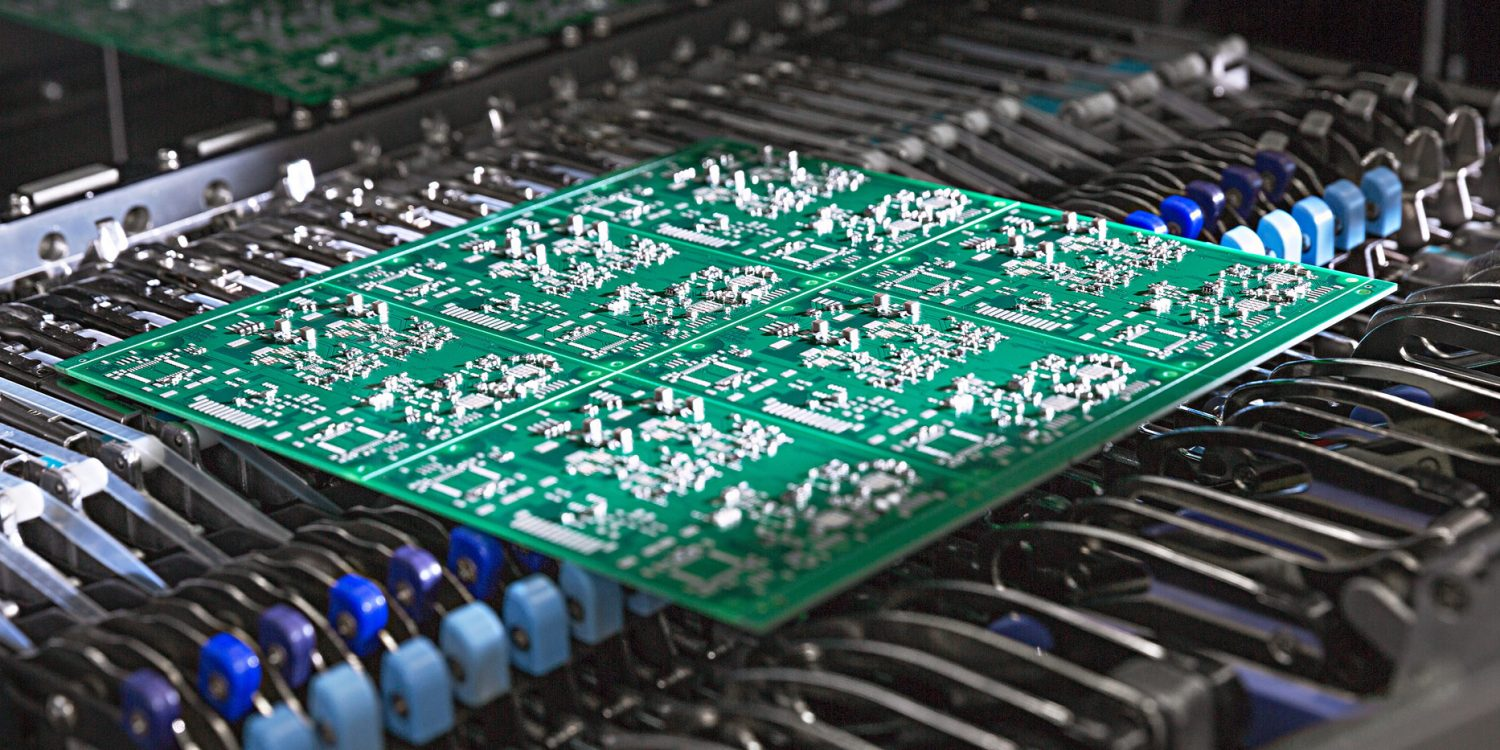

Furthermore, EMS companies are now embracing sustainability and digital transformation. Smart manufacturing techniques such as real-time monitoring, predictive maintenance, and AI-based process control are becoming standard. These advances not only enhance quality and productivity but also align with global sustainability goals.

Supply chain resilience is another key driver. With recent global disruptions, companies are seeking more robust and responsive manufacturing partners. EMS firms, with their global footprint and adaptable systems, are stepping in to provide just that.

In summary, electronic manufacturing services are no longer just about assembling products. They are integral strategic partners helping brands innovate, stay competitive, and meet the evolving expectations of today’s tech-savvy consumers.

Post time: Jul-14-2025