Box Build System Integration: Turning Assemblies into Complete Solutions

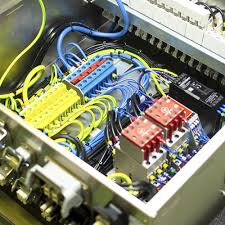

As the electronics industry continues to evolve, Box Build System Integration has become a vital service for companies looking to streamline production and reduce time to market. More than just assembling printed circuit boards (PCBs), box build integration includes the full assembly of enclosures, cable harnesses, power supplies, cooling systems, sub-modules, and final system testing.

Box build services support a wide variety of sectors, including industrial automation, consumer electronics, telecommunications, and smart devices. By outsourcing the full integration process, clients benefit from reduced supplier management complexity, lower logistics costs, and better product consistency.

A successful box build begins with detailed documentation — including assembly drawings, bills of materials (BOM), and 3D mechanical files. Engineering teams then perform a thorough review to optimize the assembly workflow, identify potential risks, and ensure compatibility between components.

Advanced manufacturing facilities now feature automated workstations, modular assembly lines, and in-circuit/functional testing capabilities. Integrated quality checks, such as automated optical inspection (AOI), vibration testing, and burn-in tests, are essential to ensure reliability.

The final product is packaged and labeled according to client specifications, with options for custom branding, serialization, and regulatory compliance (e.g., CE, FCC, RoHS). Whether the product is destined for a retail shelf or an industrial environment, system integration services help turn component-level ideas into complete, ready-to-deploy solutions.

Post time: Jun-23-2025